- Feedback

- View

Ugh. my arms hurt...

Spent 2 hours hammering this into a single 25cm long bar about 10mm thick cut it into 3, stacked and welded it then had to leave it.

Total Layers 360 (although not yet welded!)

Total weight ??

Total time so far 6.5 hours.

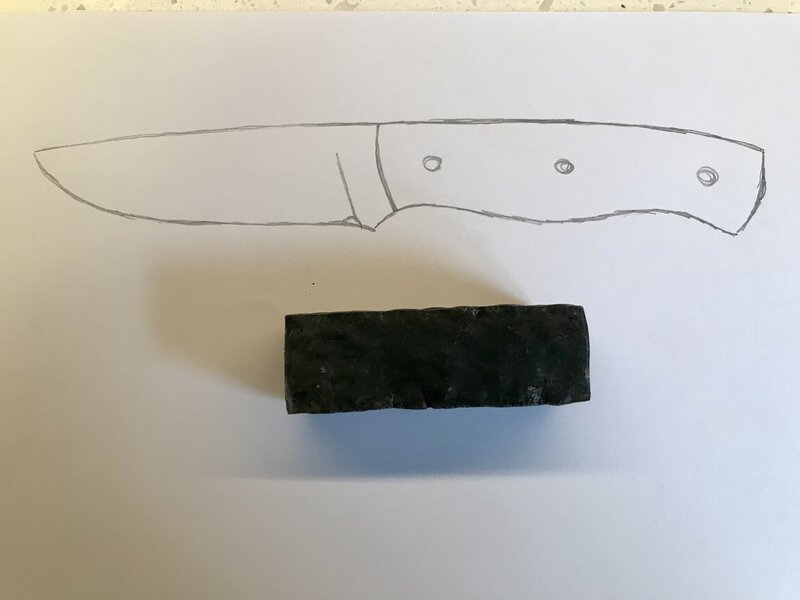

Then we get to the ball bearing canister... I don't like full tang knives for many reasons, not least I don't enjoy making them as much as hidden tang. However, I have a lot of handle scales that need using up, and should have *just* enough steel to make this work;

A nice little bushcraft style. This billet weighs 354g.

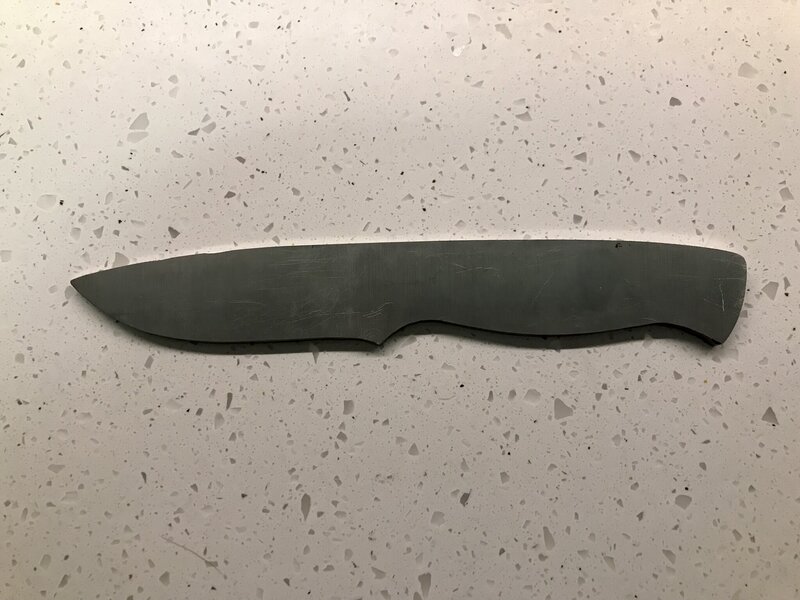

Lots of hammering, heating and yet more swearing (burnt my hand as a bit of scale jumped between my finger and the hammer) and popped in Ash for a long while to cool super slowly and anneal (soften) the steel.

A lil' bit of grinding gives this;

it weighs 184g, still a weighty little thing, and I need to take some more weight out of the handle.

Spent 2 hours hammering this into a single 25cm long bar about 10mm thick cut it into 3, stacked and welded it then had to leave it.

Total Layers 360 (although not yet welded!)

Total weight ??

Total time so far 6.5 hours.

Then we get to the ball bearing canister... I don't like full tang knives for many reasons, not least I don't enjoy making them as much as hidden tang. However, I have a lot of handle scales that need using up, and should have *just* enough steel to make this work;

A nice little bushcraft style. This billet weighs 354g.

Lots of hammering, heating and yet more swearing (burnt my hand as a bit of scale jumped between my finger and the hammer) and popped in Ash for a long while to cool super slowly and anneal (soften) the steel.

A lil' bit of grinding gives this;

it weighs 184g, still a weighty little thing, and I need to take some more weight out of the handle.